Wood Cuts: The ability to refinish hardwood elevates its value and sustainable profile – March 2024

By John Forbes

The ability to refinish a wood floor, allowing it to last for generations, is the foundational attribute that has traditionally separated real wood floors from all other flooring types. However, as the lines between hard surface categories have become increasingly blurred, many end users are unaware that refinishing an engineered wood floor is an option.

To help clarify this issue, the National Wood Flooring Association (NWFA) launched the Engineered Wood Flooring Refinishable Program in the fall of 2022. The program is a voluntary certification program designed to identify engineered wood flooring products with wearlayers thick enough to be refinished. The program also offers a list of certified refinishable wood flooring products to aid manufacturers, distributors, specifiers and end users in their decision-making processes. The program’s definition of “refinish” is consistent with NWFA’s published definition: “Sanding a previously finished floor to bare wood and applying new stain or finish.”

REFINISHABLE = RENEWABLE

The ability to refinish a wood floor not only makes it a multi-generational product, but it also ensures it will never go out of style. The color and sheen can be updated during the remodeling process or to suit the taste of a new homeowner, providing a completely new look. Regardless of the reason for refinishing a wood floor, a report conducted by IVL, the Swedish Environmental Research Institute, concluded that it is more sustainable to extend the life of a wood floor through the refinishing process than it is to tear it up and replace it.

The launch of this program is timely, as the hard surface marketplace is fraught with confusion. In a typical retail flooring store, around 80% of all hard surface flooring products have a wood look. Multilayered constructions and improved visuals on lookalikes are making it increasingly difficult to tell one product from another, and the marketing language and images compound the confusion. The word “wood,” along with pictures of wood, are being used more loosely than ever on non-wood product displays to illicit the warm feeling of real wood. The NWFA’s program is a simple tool designed to help the retail sales associate and buyer cut through the clutter and identify refinishable real wood flooring products that will withstand the test of time and add value to a home.

THE MATH OF REFINISHABLE

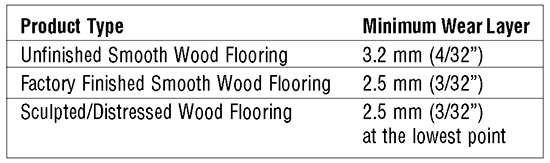

All types of engineered wood flooring products are eligible to carry the engineered wood flooring refinishable logo so long as they meet the following minimum wearlayer thickness requirements:

The rationale for choosing these minimum wearlayer thickness benchmarks is well-established. When addressing the sanding process for previously finished floors, the NWFA Wood Flooring Sand and Finish Guidelines state that, in general, if the wear thickness is less than 3/32”, the floor should not be sanded. And, for the sanding of sculpted and/or distressed floors, recognizing the variation in the surface wearlayer thickness of these products, the guidelines state that the wearlayer may be less than the recommended 3/32” thickness in many areas of the floor, which would become the lowest point that the remaining floor would need to be sanded to in order to get it flat.

Determining the wearlayer thickness benchmark for unfinished engineered wood flooring involves a little math, but not much. Prior to its merger in 2008 with NWFA, the National Oak Flooring Manufacturer’s Association (NOFMA) guidelines clearly stated that the sanding operation should remove a minimal amount of wood, less than 1/32”. If approximately 1/32” of wood is removed from the wearlayer of an installed unfinished engineered wood floor with a 4/32” wearlayer, the result is a site-finished floor with a wearlayer approximately 3/32” thick. This newly finished floor now has a “refinishable” wearlayer comparable to a newly installed factory finished floor. The 4/32” wearlayer benchmark is further supported by standardized detailed drawings for the thinnest solid unfinished wood floors (3/8”) dating back as far as 1916 that show 4/32” wearlayers, which allowed the resulting wood flooring product to be sanded and finished onsite and refinished at least once at a future date.

An inches-to-metric conversion chart will illustrate that 3/32” equals 2.381mm. It is true that rounding 2.381 mm to 2.5mm makes it easier to communicate, but that is not the primary reason for the rounding. The European Federation of the Parquet Industry (FEP) unites Europe’s parquet manufacturers, associations and suppliers. The European wood flooring category faces the same hard surface market challenges that we contend with in North America. In order to safeguard the quality image of parquet, as well as push back against the myriad of lookalike products, FEP developed its definition of parquet around wood flooring’s ability to be refinished; for the last 20 years, a wood flooring product can be called “parquet” in Europe only if its real wood top layer is at least 2.5mm thick. To encourage an international norm, NWFA has aligned its refinishability benchmark with FEP’s definition of parquet and has developed a compliance path in which FEP-certified refinishable parquet products from Europe can be cross-certified within the NWFA Refinishable Program.

This standard has been implemented in an effort to alleviate the blurred lines between hard surface categories, and to help the consumer understand the value of their real wood floor investment. Some suppliers that produce certified refinishable products go so far as to put stickers on their samples so the consumer knows they are buying a quality product that can refinished for an extra lifecycle.

Copyright 2024 Floor Focus

Related Topics:NWFA Expo