Manufacturing Technology - Aug/Sep 2013

By Jessica Chevalier

Often, we pull back the curtain to see how the newest flooring designs are being created—considering how carpet tile is designed and constructed, how hardwood is texturized, how the new ceramic tile looks achieve their high shine, to name a few examples—but it’s less often that we take another step back to consider how manufacturing technology enables flooring designers to create these new product formats and aesthetics.

Of course, advancements in technology aren’t only about visuals. Increasing efficiencies that reduce cost and improve quality are just as important in revolutionizing the industry and, to that end, machinery manufacturers must continually engineer machines to increase processing speed, conserve raw materials and resources, find and resolve problems with regard to production, and be simple to access and fix when repairs are needed.

There are a handful of machinery manufacturers that serve the U.S. flooring market, many of which are headquartered only a short drive from Dalton, Georgia. Though machinery sales were slow in the recession, now that consumer demand is increasing, flooring manufacturers are once again investing in new equipment to optimize their efficiency and boost their output. As a result, some machinery manufacturers are experiencing great demand for their products. CMC, for example, builds five to six carpet tufting machines per month and is now operating on an eight-month backlog.

MACHINERY INNOVATIONS

Located in the Netherlands, Matrix Vision started in 1978 as a micro-electronic development company. After several years of developing products for others, Matrix began creating and marketing products under its own name. In 1982, the company developed its first line-scan camera; in 1987, its first pile detection system; and in 1990, its first thread detection system (TIS).

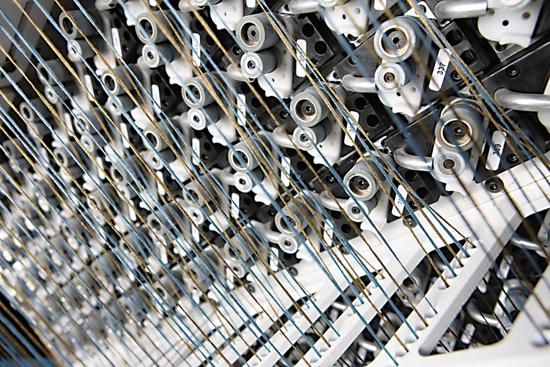

Recently, Matrix introduced the second version of its TIS. The TIS system addresses one of the most basic problems with tufting: lost ends. TIS looks under the needle tips to see if the yarn is missing. Once TIS detects three stitches with a missing end, it stops the tufting machine so that the defect can be repaired. The TIS will detect over 99% of missing ends, claims the company.

The new version of TIS uses a system of mirrors and lenses to provide the array of cameras (the scanner) with a closer view of the needles. In addition, the tufting machine’s pressure foot is replaced with one that has a red light bar, which provides illumination, making it possible for the scanner to see every yarn due to the contrast.

This system helps minimize the need for mending carpets, which is a time-consuming process and sometimes impossible to do well in expensive goods. It also increases the efficiencies with regard to manpower, as an individual is not needed to check the end product for defects. Ultimately, this saves cost.

In the coming years, Matrix may resurrect and improve upon its pattern verification system (PVS) technology. The PVS system was invented by the company years ago but was discontinued because it was too complicated to operate. PVS would use the same scanner that TIS does and would look at the pattern of stitches on the back of the finished carpet to detect disruptions that indicate defects.

Card Monroe Corporation (CMC) specializes in carpet tufting technology. The company was founded in 1981 by Lewis Card Sr. and Roy Card, nephews of the Cobble brothers, who began manufacturing tufting equipment for chenille bedspreads in the 1930s. CMC claims to have over 2,000 machines in operation across the world and reports that it has sold over 110,000 of its Infinity motors since 2002.

Two years ago, CMC developed a new product that builds off its Colorpoint technology, which was first introduced in 2008. Two-Color Colorpoint combines Colorpoint technology with LCL technology for a product that provides new opportunities in styling for the residential and hospitality markets. The resulting product has no buried end with full gauge coverage on the face, which means increased durability. The machine allows for pinpoint color placement in any pattern the designer would like, and the two yarn colors used can be combined to create a third color effect. Previously, the only way to pattern loop carpet was through printing or by creating a pattern with different loop heights.

Two-Color Colorpoint enables users to do all cut pile or patterns with varying amounts of cut and loop. The company will soon have six machines in operation in the U.S. market. And Two-Color Colorpoint machines are backwards compatible, meaning that they can be used to manufacture traditional LCL patterns as well.

The family of Colorpoint products began with Colorpoint Loop and Colorpoint Cut and Loop in 2008. The original Colorpoint machines allowed the use of up to six colors. Initially, the machine was created for carpet tile. Today, there are 33 Colorpoint machines in use, about 22 of which are producing carpet tile. Like the other Colorpoint machines, Two-Color Colorpoint also utilizes CMC’s Infinity Pattern Attachment.

CMC reports that over 95% of cut pile machines in use in the U.S. are theirs.

Founded in 1960 as Southern Machine Company, Tuftco is another Chattanooga based equipment manufacturer that designs and builds tufting machines for the carpet industry. The company diversified and expanded its product line in the late 1960s to include finishing equipment and yarn delivery systems. Today, Tuftco can provide a carpet manufacturer with a turnkey carpet manufacturing facility.

Most recently, Tuftco developed its new iTuft yarn control and operating system. iTuft is a series of tufting machine pattern attachments and their related operating systems that act as a precise yarn control system. iTuft controls every yarn in the tufting process for pattern loop, pattern cut or pattern cut and loop constructions. It can be used for both dense and more loosely tufted carpet.

iTuft comes in five different configurations: iTuft single end, iTuft 2e, iTuft 3e, iTuft 4e, and iTuft 5e. The numeral refers to the number of repeats across the width of a tufting machine. With the iTuft single end, a manufacturer that produces 12-foot wide goods could create a carpet with a 12-foot wide logo, for example, something that might be desirable in a casino.

The precision of the machine offers sharper critical pattern breaks in color and texture, quicker transitions from high to low pile tufts, and less yarn consumption from a tighter backstitch.

The iTuft frame is configured so that all critical components of the machine are accessible from the manufacturing floor, which means that technicians don’t have to climb to the top sections of the machinery for many repairs. In addition, the platform offers remote diagnostics, so that users can access production statistics such as efficiencies, daily output and future scheduling from other locations.

Oerlikon Neumag is the U.S. arm of Oerlikon Manmade Fibers. The Neumag arm also serves the China and Turkey markets. In Asia, the company is known as Oerlikon Barmag. Oerlikon makes filament spinning systems used for manufacturing manmade fibers, texturing machines, BCF systems, staple fiber spinning systems and artificial turf systems. The company has its headquarters in Switzerland.

Oerlikon Neumag has recently introduced several new technologies aimed at lowering energy consumption, increasing efficiency, lowering waste rates and increasing throughput for customers using its technologies.

In 2012, Oerlikon Neumag released its latest BCF spinning line, S+, for PET applications. The machine is a three-yarn end line that combines the advantages of the company’s S5 and Sytec systems. S+ offers a high process speed with stable spinning performance. In addition, the machine was engineered to make maintenance easier. S+ offers efficiency of 99% and a significant speed increase from earlier machines.

The company also developed a new intermingling device called Rotac, which brings performance improvement to the single yarn-end line Sytec One system.

Lastly, Oerlikon is offering new bicomponent spinning technologies for all Neumag BCF lines.

Located in Soddy Daisy, Tennessee, just outside of Chattanooga, Hasko Inc. is a strategic alliance that consists of three groups: Hasko Inc., Haskan Technologies and Mekanika.

Hasko Inc. designs and builds machinery for solid and engineered wood flooring plants, offering single machines and systems as well as turnkey solutions that include plant layout, design system and machine integration, and implementation. Haskan Technologies creates wood scanning systems for defect cutting and rip optimization for solid and engineered wood flooring, and Mekanika designs automated material handling systems for most all areas of the solid and engineered wood flooring industry. Hasko Machines has been in operation since 1930.

Under the Hasko brand, the company has introduced several innovations recently. To start, it developed a shifting gang ripsaw for ripping flooring blanks in solid wood flooring plants. The system offers more flexibility for plants to produce the expanded mix of widths and species desired by today’s customers, while increasing raw material utilization by increasing board yield. In addition, Hasko developed a multistage process that improves sanding operations in solid and engineered prefinished lines. This system increases production, while decreasing in-process defecting and reducing finish line labor.

Lastly, under the Hasko brand, the company introduced the MPEM Wood Flooring End Matcher, an improved machine for applying tongue and groove profiles on the ends of random length solid and engineered flooring. The machine offers improved dust extraction and requires no operators when integrated with associated plant automation.

Under Haskan, the company developed the Ultra Scan, a scanning system for internal defects in wood. Ultra Scan has been in development for the last six years. And under the Mekanika name, the company recently developed a system for measuring, sorting by grade and nesting for boxing and strapping. This amounts to a reduction in labor for both solid and engineered flooring manufacturers.

The company explains that 65% to 75% of the total cost of wood flooring is from raw materials, so even a slight improvement in yield brings greater profits. Says Randy Brooks, president of Hasko Inc., “Today’s flooring manufacturer typically uses $30,000 per year per worker for pay and benefits. A five year payback on a $1,000,000 investment would normally require the elimination of six to eight workers/shifts.”

B Carpet, formerly Burtco, creates custom carpets for the hospitality industry. Though the company isn’t in the business of selling machines to other manufacturers, its new Octacia machine, the creation of B Carpet and CYP Technologies, is unique in the industry.

Octacia builds on the company’s Tapistron computer yarn placement technology, expanding to include a larger palette of eight colors, something that the company claims no other CYP machine in the world can do.

CYP products generally compete with woven products in the marketplace. Axminsters, usually wool nylon blends, are limited to cut pile constructions, while CYP products can be cut pile, loop pile or cut and loop designs, using either wool or solution-dyed nylon. Where CYP typically falls short to wovens is in color options. Octacia expands B’s CYP color palette by 33%. The technology also enables the company to make various tuft densities and easily run between 100 and 200 tufts per square inch. The company anticipates that the next generation of this technology will bring advancements in deepening contrast levels in the pile heights for richer textures.

Unlike with other tufting technologies, no additional yarn goes on the back of the carpet with Octacia, which makes it easy to apply a secondary backing.

B Carpet, then Burtco, started producing custom-crafted carpet for the hospitality market in 1979.

Laminam is the porcelain tile manufacturing arm of Italy’s System Group, which creates ceramic tile manufacturing technology. In 2001, System Group created Lamina technology, a new method of producing large format ceramic tile, and sold it to four different groups (two in Spain, one in Italy and one in Turkey). These four firms implemented the technology but began cutting the tile, rather than selling it in large slabs. System Group didn’t feel that this was the right application for Lamina, so in 2006, it delved into the production of tile, calling the new endeavor Laminam, and started producing large format porcelain sheets.

The Lamina technology was created in response to a perennial challenge with standard ceramic and porcelain tile. When tile is manufactured using the standard method, powder is poured into a mold then pressed for three seconds with between 4,000 and 7,500 tons of pressure. Because the sides of the mold prohibit the release of air, the resulting product is riddled with air bubbles that can cause warp-age, fragility and a lack of consistency. These issues are controllable in small formats, reports Piergiorgio Mazzetta, North American business development manager for Laminam, but once sizes reach larger than 24”x24”, they can cause failures.

To eliminate problems caused by trapped air, the firm created a new system for manufacturing ceramic tile. Rather than using a mold with sides, Lamina distributes powders onto a conveyor tape with no edges, then presses the materials for 70 seconds under 30,000 tons of pressure. As the air is leaving the tile, it breaks the edges, which then must be trimmed away before the tile is glazed and fired. The resulting product is 3mm thick and completely flat.

Crossville distributes Laminam’s 3+ product in the U.S. market; this product is not recommended for floor use but rather for cladding or as an architectural skin. However, in October, the company will introduce Laminam 5+, with a 5.6mm thickness, that can be used as flooring.

EFFICIENCIES

While machinery plays a large part in producing an efficient manufacturing process, additional efficiency is achieved simply by how a facility is constructed. Both Engineered Floors and IVC have new plants in North Georgia that, since the factories were built from the ground up, are models of manufacturing efficiency.

Many of the large carpet mills have grown by acquiring different steps of the manufacturing process—buying up extrusion and backing businesses, for instance—after which their operations are often spread apart, sometimes by as far as several states. In these cases, the businesses must utilize a sophisticated logistics network to move materials through the manufacturing process. Sometimes as many as four interplant transfers are made in the production of one product. Of course, this costs money—in man-hours, fuel and machinery—and impacts the cost of the finished products.

At Engineered Floors, however, every part of the manufacturing process is completed under one roof. “Everything flows right through the plant,” says James Lesslie, assistant to the chairman at Engineered Floors. “As far as I know, ours are the only plants that take polymer in one door and finished carpet out the other.” Currently, Engineered Floors has two plants, a 650,000 square foot facility in Calhoun and an 850,000 square foot facility in Dalton. The company plans to open a third facility in Whitfield County, Georgia that will be even larger then the first two.

In its effort to create the most efficient plant possible, the company sought out what Lesslie calls the “latest and greatest technology,” and found that the heatsetting process was one where the firm could make strides. Normally, a heatsetting machine runs 48 ends at a time, but Engineered Floors’ Superba heatsetting machines run more fiber through the tunnel at once, either 60 or 72 ends. This cuts down on energy use and increases operational efficiencies.

But the biggest gain in efficiency that Engineered Floors has over many mills is in eliminating the dyeing step completely. Engineered Floors uses 100% solution-dyed fiber, which streamlines the tufting process but also means that a company is “married” to the color it chooses at the outset, regardless of market trends.

Engineered Floors commissioned a university study on its processes to quantify its energy savings. The study, which according to Lesslie is about 99% complete, determined that, in comparison to other carpet mills that use a dyeing process, Engineered Floors is saving 30% in energy, using 87% less water and generating 42% less greenhouse gas.

Like Engineered Floors, IVC finds efficiency in outfitting its factories with the latest technology. Says Paul Murfin, co-CEO at IVC U.S., “One of the core philosophies of IVC is dedication to the latest and greatest in technology. We have three sheet vinyl plants and one LVT plant. We embrace the latest in all of them and focus on having more equipment than people. Since many competing products come from the Far East, where labor is cheap, you need to leverage technology to be competitive.”

One process that differentiates IVC from its competition is in how its Belgium plants creates the top layer for its LVT. Rather than purchasing designs from one of the manufacturers that sells them, as most LVT manufacturers do, IVC manufacturers the top layer on its sheet vinyl line. In addition to creating visuals unique to IVC, this process yields other benefits. First, the product has two layers of glass fiber rather than one, which means it’s more dimensionally stable than its competitors, and, second, because the top layer is created in one meter by one meter sheets, the repeats are longer, resulting in a more varied and realistic look in the final floor.

Murfin says that one of the challenges related to efficiency is keeping up with technology, which is changing so rapidly. In other words, what’s new and efficient today is likely to be outdated tomorrow.

IVC is adding a fourth shift at its Dalton sheet vinyl plant and plans to open an LVT production facility at the site as well.

|

MAINTENANCE & REPAIR |

|

Manufacturing machines aren't only improving the efficiency with which they make product. Several manufacturers are also working to make their machines easier to repair, which will also reduce time lost as well as the potential for acidents. In the past, working on a tufting machine often required technicians to climb to access parts of the machine, but Tuftco is now engineering its machines so that all critical components are within easy reach from the floor. |

Copyright 2013 Floor Focus

Related Topics:Engineered Floors, LLC, The International Surface Event (TISE), Tuftco, Crossville