Importing Green - August/September 2010

By Darius Helm

There’s a reason the U.S. Green Building Council gives LEED points for locally manufactured product—the greater the distance between production and consumption, the higher the environmental burden. It’s a formula that often makes economic sense as well—no matter how green the cheese, it’s probably not worth the trip to the moon to get it.

In the flooring industry, the biggest volume of imports comes from the commodity side of the business, low cost versions of products like ceramic tile and vinyl from China and other Asian manufacturers. On the other end of the spectrum are the high end specialty products for which there are no American equivalents, like handmade Persian rugs or West Africa’s zebrano hardwood. More relevant to discussions of sustainability are two of the greenest products out there, bamboo and cork.

PORTUGAL’S CORK

Cork comes from the bark of the cork oak, a species found predominantly in Portugal, as well as in Spain and parts of North Africa like Morocco and Tunisia, but it’s Portugal that dominates the industry. According to APCOR, the Portuguese Cork Association, while Portugal accounts for 32% of the cork forests, it accounts for over 50% of annual production.

The thick bark, elastic and impermeable, is harvested every nine years in a process that has no negative impact on the tree itself. The bark, 2” to 3” thick, is used largely for wine stoppers, and cork floors are generally made out of the post-industrial waste from wine stopper production—essentially waste material from an already sustainable bio-based industry. The cork bark itself has anti-bacterial and anti-fungal qualities, and because of its unique cellular structure, it will retain its elasticity (and performance characteristics) for, in some cases, centuries.

When it comes to carbon sequestration, cork has a particularly attractive profile. According to APCOR, cork bark harvested after nine years makes up 4% of the tree’s biomass production over the same period. The carbon content, which accounts for about half its weight, remains in the cork for the life of the product. That rapid rate of carbon sequestration makes cork a more effective carbon dioxide scrubber than most of the flora harvested for product across the world, with the average cork forest snagging from the atmosphere 2.3 metric tons of CO2 per acre per year.

Here in the U.S., cork flooring is a rapidly growing product category, and it’s hugely popular in the designer-oriented contract market for its captivating looks, high performance characteristics and sustainable profile. In terms of performance, it’s often specified for its acoustic insulation, thermal insulation and comfort underfoot. The product itself is far more resilient than the impression one might get from fiddling with a wine cork at the dinner table. As an example, high end cork handbags on the market reveal a texture closely resembling leather.

There are a number of cork players in the U.S. market, like WE Cork, Expanko, Capri Cork and Amorim, the largest producer in the world, best known for its Wicanders brand. Amorim is also the one that makes the stylish handbags, along with wallets and belts.

One commercial brand, USF Contract, a division of US Floors, recently came out with Cork Colors, a palette of 36 subtle and sophisticated colors in seven construction patterns to broaden the product’s design range. The firm’s commercial cork is largely gluedown, though the residential division features floating tiles and planks.

USF Contract’s portfolio is based on a range of rapidly renewable and responsibly harvested products, so not only does it sell cork, but it also offers a large bamboo selection and FCS Pure certified hardwoods. The firm’s bamboo collection includes traditional horizontal and vertical constructions, as well as strand bamboo, which looks less like bamboo and more like a dramatically veined hardwood.

USF Contract’s green programs extend beyond products to process. For instance, the 144 kilowatt solar array on its warehouse, in the process of being expanded to 355 kilowatts, is, according to the firm, the largest commercial solar array in Georgia. USF Contract is currently pursuing LEED NC Gold certification for that warehouse. And by the end of the year, the roof of its manufacturing facility, already partially covered with solar panels, will be entirely devoted to solar, producing over 250 kilowatts. In addition, the firm ships its products on the Evergreen Line, a freight company with a strong sustainability program.

CHINA’S BAMBOO

Neither cork nor bamboo are hardwoods, and while cork is tree bark, bamboo is, strictly speaking, a grass. The type of bamboo used for flooring, moso bamboo, comes almost exclusively from China, and when it’s dried it’s harder than most domestic hardwoods. Traditional engineered and solid bamboo is harder than oak, ash or maple on the Janka hardness scale, and strand bamboo is harder even than Brazilian cherry, so in terms of performance it’s effectively a hardwood. It’s also competitively priced with domestic hardwoods, which has helped it gain a foothold in both the commercial and residential markets.

Moso bamboo is harvested about every five years, which is how long it takes it to grow 80 feet high and about 6” thick. The wall of the stalk, by that time at least one inch thick, is used in strips to make bamboo flooring. Mosa bamboo is also pulped and turned into a soft, strong fiber, increasingly used as a textile for everything from scarves to socks.

Like cork, bamboo is notable for its rapid carbon sequestration, and when the bamboo shoot is cut and harvested, new shoots grow from its base, unlike, for instance, a hardwood tree.

Until recently, bamboo flooring came in only two colors, natural (a light straw tone) and carmelized, where the sugars are cooked to darken it into a deep, warm hue. Increasingly, bamboo producers are staining it for broader appeal, and stained strand bamboos are being marketed to compete with less sustainable exotic hardwood species.

Teragren, headquartered in Bainbridge Island, Washington, sells the bulk of its bamboo to the residential market, though its commercial business is steadily growing. The firm’s supply comes from its exclusive partner factory near Shanghai, China that sources its bamboo from local, family-owned bamboo plantations.

The firm’s U.S. headquarters gets all its energy from wind power, and it’s carbon neutral. According to the firm, internal studies have concluded that its entire operation is carbon negative, and Teragen is in the process of pursuing third party certification for that claim. That carbon negative status is largely due to the bamboo’s carbon sequestration—the firm estimates that the maximum transportation of a given product, by ship from China to the West Coast, by train to Chicago and by truck all the way to Maine, emits carbon dioxide equal to only 25% of its sequestered volume. The firm transports its products across North America through ABS Freightways, a progressive transportation company that, for instance, uses low sulfur diesel for transportation through metro markets.

Another major U.S. bamboo supplier is Home Legend, which also offers bamboo, cork, hardwood, laminates and area rugs. The firm offers 28 SKUs of bamboo flooring, including solid horizontal constructions, engineered horizontal constructions with a Uniclic glueless system, vertical engineered constructions and strand woven bamboo, both solid and engineered. The products are available in a range of traditional hardwood tones. The high density fiberboard cores used for the engineered constructions are all CARB compliant with low emissions.

Home Legend’s bamboo is shipped from China in full container loads, though the journey, which used to take about two weeks, now takes closer to three, a pace that has reduced fuel consumption and carbon emissions.

Another prominent bamboo producer is Smith & Fong, which does about 70% of its business in the commercial market. The firm’s bamboo products are certified formaldehyde free, and the entire range is available FSC certified—it’s standard on a lot of products and available by request on the rest.

Bamboo, under the Plyboo brand, makes up about 85% of the firm’s product line. In addition, Smith & Fong offers palm flooring, sustainably harvested, and an FSC certified domestic hardwood line called Sideways.

SHIPPING BY LAND AND BY SEA

One issue that comes up in discussions of the environmental profile of cork and bamboo is the impact of shipping these products across the ocean. In the case of bamboo, it’s shipped from the other side of the globe. However, while it’s true that crossing the ocean adds significantly to the environmental burden of the products, a closer look at the numbers reveals that in many cases transporting the products across the U.S. to distributors and retailers is in fact an even bigger environmental burden.

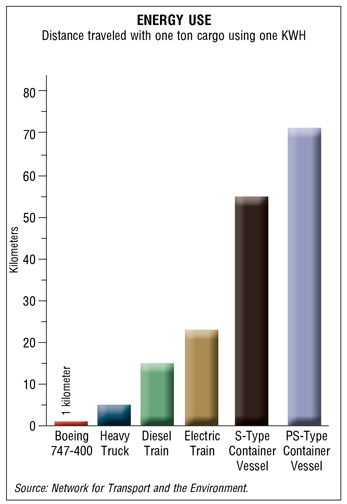

Several years ago, Sweden’s Network for Transport and the Environment did a comprehensive study of the comparative burdens of shipping by land, air and sea. The big loser, transportation by air, is not relevant to the freighting of flooring, but comparisons of truck, rail and cargo vessel transportation are particularly revealing.

For instance, measured by grams per ton per kilometer, large container vessels emit 7.48 grams, compared to 18 grams for electric trains and 50 grams for tractor trailers. And in terms of energy use, kilowatt hours per ton per kilometer, large tankers clock in at 0.014 kilowatt hours, compared to 0.043 for electric rail and 0.18 for trucks.

If all that seems a little obscure, let’s look at it in terms of energy use—how far each mode of transport can move a given weight of product with the same energy consumption, measured in kilowatt hours. For every mile a tractor trailer can travel, a diesel train can travel three miles, an electric train can travel about four and a half miles, and large container vessel can travel 14 miles. So a 5,000 mile journey by sea between China and the West Coast would be equivalent to a 360 mile journey by tractor trailer, less than the distance between Atlanta, Georgia and New Orleans, Louisiana.

While there’s no question that shipping product around the world has a negative impact on that product’s environmental footprint, in the case of cork and bamboo, it’s still a positive result in terms of carbon sequestration. In addition, it can often be greener than transporting a product across large distances in the continental U.S.

Copyright 2010 Floor Focus