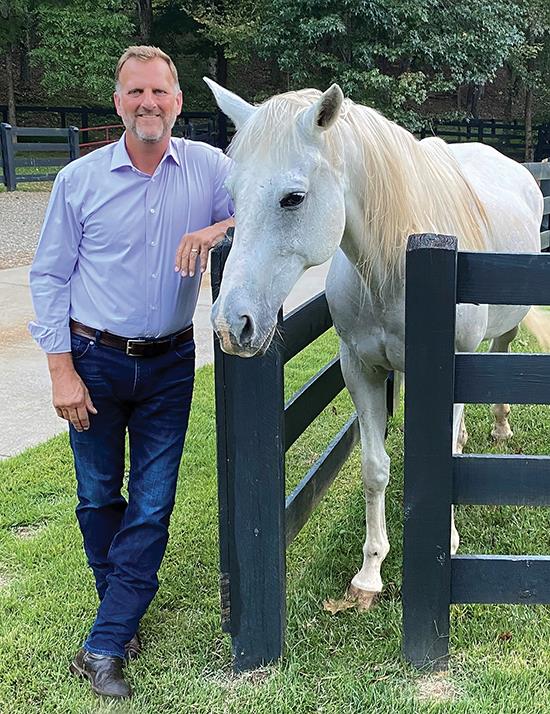

Focus on Leadership: TM Nuckols is preparing The Dixie Group for its next 100 years – October 2022

Interview by Kemp Harr

From a farm kid in rural Virginia to president of The Dixie Group (TDG), TM Nuckols has stood in many shoes throughout his life but pulled from the same well of strengths: hard work, faith, and a willingness to listen, learn and change. During his early career in fiber at DuPont/Invista, TM became acquainted with The Dixie Group, which he felt offered “a very clear picture of what my future would look like.” He joined the company in 2017 as executive vice president of Dixie’s residential business, and was named president of residential business later that year.

Today, TM lives with wife, Kimberly, in Acworth, Georgia; the pair have two grown children: Austin (28) and Heather (23).

Q: Tell us a little bit about your background.

A: I grew up on a farm northwest of Richmond, Virginia. The area was known as Short Pump. I am not joking. Today, Short Pump has developed into a trendy area, with high-end outdoor shopping and restaurants. But when I was growing up there, it wasn’t the place you wanted to be from; people made fun of you if you were from Short Pump! But I wouldn’t trade it for anything.

I was the youngest of five, with four older sisters, and both sets of grandparents were on the farm with us. We had cows and pigs, so I learned at a pretty early age to respect animals and how to take care of them. I really got into sports as a kid, and that spilled over to my high school years and beyond. I am still pretty active today; it keeps my competitive juices flowing!

I grew up working for my dad at his Exxon service station. This was a full-service station where we would pump gas and clean windshields out front with a full repair shop in the back. So, I learned a little about working on cars and a lot about dealing with people. One thing I learned from my dad was work ethic; between the station and the farm, I have never seen anyone work harder than he did. It was all he knew.

I decided on the University of Virginia (UVA) my senior year in high school. UVA was a very good school, and Charlottesville was pretty close to where I grew up. I graduated from UVA with a BS in electrical engineering in 1989.

I was raised in a Christian household, and for that, I am thankful. This foundation has guided me through the twists and turns we all face in this life. My faith is strong, and I lean on it through the good times and the bad: the God of the mountain is also the God of the valley.

I met my wife, Kimberly, in high school. Having her by my side all these years has really been a blessing. She is an animal lover, and we live on a small farm in Acworth, Georgia with horses, dogs and cats!

Q: What led you to pursue a career at DuPont in the textile field?

A: I suppose it really came down to money. Two companies offered me jobs when I graduated from UVA. One was a paper company. The other was DuPont, and the job was in its engineering field program, where I would rotate through various positions over the first few years of my career, then decide where I wanted to focus.

DuPont’s offer was $2,000 higher than the other, so I took it! I was placed in the Waynesboro, Virginia fiber plant for my first assignment, and the plant didn’t let me move on to other locations! As it turned out, I would never leave the fiber business during my time with DuPont/Invista.

Q: What were your most noteworthy achievements during your 27 years with DuPont/Invista?

A: Throughout my career at DuPont, I always seemed to end up in the most challenging roles. My first business role was in DuPont’s Lycra business in 1997. I was the North America supply chain manager, and my job was to make sure we maximized the availability of product to other parts of the world, especially Asia. I had to work with the North America sales teams to meet their needs while allocating every possible pound of fiber to export. I learned a lot in that role about seeing the big picture and maximizing business, and that year Lycra was either the number one or number two business in the entire company for profitability.

One day my boss asked me to travel with some of our salespeople to see how I liked being in front of customers. The very first customer visit I made was to a core-spinning operation in Chattanooga. That customer was Dixie Yarns.

I joined DuPont’s nylon flooring business in 2001. After a few months calling on automotive segment customers, Steve Griffith pulled me into the residential business, and that really set my course for the rest of my career. After several years of working directly with manufacturers, including Mohawk, The Dixie Group and Pharr Yarns, I was moved into the role of product manager. We developed several new fiber programs, including Luxerell, TruSoft and SolarMax, a solution-dyed nylon program that would later become PetProtect.

I would eventually be asked to lead the national accounts programs, including the buying groups and home center channel. A couple of years later, leadership for the field organization was added to my role. In 2015, I was moved back into the product and mill sales group to lead our product strategy and mill sales execution.

Q: How did your tenure at DuPont/Invista prepare you for your current role at The Dixie Group?

A: Spending ten-plus years in DuPont’s manufacturing, production planning and supply chain areas put me in position to move into customer-facing roles. And, after 15 years in various positions in the Stainmaster business, I had developed a good background and base of experience in the residential carpet business.

Early on in my Stainmaster days, I gravitated to a product-centric approach-working with my mill accounts to launch as many new Stainmaster products as possible. I developed a good eye for product and learned a lot about how various yarns could be used to create certain looks and aesthetics in carpet. Later, working in the national account and specialty retail segments helped me see business from a different perspective and develop relationships in those areas. I would also have to say that the Koch business philosophy was a key learning point for me, especially the importance of creating a vision of a better state and having the right talent in the right roles to achieve the vision.

Q: Who are your mentors, and what did you learn from them?

A: First would have to be my parents. From them, I learned about hard work, integrity, common sense and doing the right thing. And from each of them, I received a competitive spirit.

From this business, I would have to start with Mike Goodall. I worked for Mike at DuPont/Invista before he moved on to Mohawk. From Mike, I learned about yarn and products and using new products as a way to be successful in growing the business. Although I was not a yarn or tufting expert, I developed a good eye for product, and that came from working closely with Mike.

I have to include Steve Griffith as well. Steve led the Stainmaster business for many years. He was very smart and very analytical-maybe too analytical sometimes. Steve created something very special with the original DuPont Flooring Center program. From Steve, I saw the importance of having a solid strategy, which is layered through the value chain, and how important key relationships are in executing the strategy.

There have been many other leaders in this industry I have been fortunate to cross paths with: Fritz Munzinger, David Polley, David Hardy, Paul Comiskey, Mike Derderian, Bip Carstarphen and many others.

Q: Dixie has gone through some serious changes since you joined. What has driven these decisions, and has the company adjusted its core competency along the way?

A: The Dixie Group is a great example of embracing change and evolving as a company. We started over 100 years ago as Dixie Mercerizing in the cotton yarn business. Over the years, we moved from natural yarns to synthetic textile yarns to carpet yarns, and eventually to carpet manufacturing with the acquisition of Masland in the early ’90s. We are only around today because of the company’s willingness to make the necessary changes as market conditions changed over the years.

Today, my primary goal with TDG is to create a more diversified base of business. Five years ago, we were a carpet company with a residential and a commercial business. Within our residential business, we had one segment, nylon carpet, and almost all of that was branded Stainmaster. Essentially, all our eggs were in that basket.

We got to work developing an alternative nylon program using type 6,6 nylon. This would become our EnVision66 program and would prove to be a critical step down the road, because it gave our product development and manufacturing teams some experience with how to develop and produce high-end carpet with other nylon fibers. That has helped a lot with all the fiber conversion activity we have dealt with in the wake of the Invista exit.

TDG was already planning to launch hard surface when I joined in early 2017. Our team did a fine job with the initial launch, but we did not have the experience and knowledge of this segment to really be successful. After several months of searching, I had the good fortune to cross paths with Jamann Stepp, who joined us in mid-2018, and after four years, really has our hard surface programs going in the right direction.

We have announced the conversion of our Atmore, Alabama facility from carpet to hard surface manufacturing. We have a facility and people, and we no longer need the carpet capacity. We have a joint venture partner that is very experienced in manufacturing luxury vinyl flooring. This partnership is a win-win for both companies. For us, it certainly creates the opportunity to better serve our customers and our growing hard surface business.

I see the same kind of opportunity in the decorative segment. We have been in the wool business for well over a decade. But for years, we have been focused on internally tufted wool products, while the market has moved to more imported woven styles. The addition of Len Andolino is the key for our success here. He knows the market, the suppliers, the price points, the customers. And he has a great eye for product. I am very excited and confident in this initiative with our new brands, 1866 by Masland and Décor by Fabrica. It is taking a major investment in product and talent, but the long-term benefit to the company is significant.

In addition, Pami Bhullar was named vice president of business development in February 2021. Pami is regarded by many as the best sales trainer and motivational speaker in the industry. He is working directly with our retail partners and our sales teams.

Lastly, Bill Storey is one of the most highly respected leaders in this industry. With over 30 years at Karastan, he understands the high-end segment, and he understands brands.

Q: How have you involved your team with these decisions and built buy-in that the company does have a plan and intends to be around another 100 years?

A: I am a huge proponent of creating a vision of the future-where do we want to be?-and getting everyone on board with understanding where we are trying to go. When that happens, it is not hard to reach your destination. Get the team on board with where you are trying to go, and, if it makes sense, they will take you there!

Q: Those close to Dixie know the turmoil you’ve faced in converting your yarn supply as your former company switched from largest supplier to a disrupter of your business. How did you lead the company successfully through this?

A: Invista’s actions have had a significant impact on us. There has been the direct impact-selling the brand, then raising prices by exorbitant amounts, then cutting off supply-but there have also been second- and third-order effects of those actions.

The fiber conversion project has been a challenge. In white nylon, we had been using about 20 different Invista fibers, which were blended in various forms to create nearly 70 yarn SKUs. And these fed into 150+ carpet styles and 3,500+ carpet SKUs. On solution-dyed nylon, we had 32 Invista fiber colors in over 170 yarn SKUs used in 80+ carpet styles. It has been a mountain of a task. But the product development, manufacturing and quality control teams have all done a great job of working through the process. At this point, we are essentially done with the development work, and all but a handful of styles have been approved on the new yarns.

I mentioned the second and third order effects of the Invista exit; that is, the actions of others caused by Invista. For example, when Invista sold the Stainmaster brand to Lowe’s, it agreed to supply BCF fiber for two years. However, within a couple of months, Invista started raising prices by huge amounts-$0.50 to $0.75 per pound. This was unheard of, and there was no justification for it.

In turn, Lowe’s conducted a full-line review of the whole floor, and the end result was a complete shift in strategy and a wholesale move away from nylon 6,6. Although we had been a good supplier to Lowe’s for years, we were caught in the middle, and our products were no longer a good fit for their strategy. The loss of that volume has had a significant impact on us this year.

The good news is, we are near the end of the conversions. We are working through the last of the inventory of Invista material. We now have multiple nylon suppliers and are in a better position from a supply base, which protects us and our customers. We are in control of our own destiny.

Q: As you bring in young talent to replace those who retire, what is your biggest challenge?

A: Experience is hard to replace. Intrinsic knowledge is lost every time we lose a sales rep or a manager who has been in the industry for 40+ years. And we have a lot of folks with that kind of experience.

At the management level, we have been addressing this by promoting some of our younger folks and having them work closely with our more senior leaders. At the sales rep level, we look for the best talent we can find in the local market. And we look for individuals who are a good cultural fit for TDG.

Q: How do you balance your work life with your family and spiritual life?

A: That’s a tough one. I try to remember this priority: God first, family second, then everything else, which is where work falls. That is a pretty good compass for me to try and follow.

From a spiritual standpoint, I start my day in the office in scripture, which puts me in the right frame of mind for the day.

Q: What do you do for fun?

A: I mentioned earlier that I am very competitive. I love sports and am active in golf and tennis. I love being in the game, grinding out the tough points, and pushing myself to win. I also love wakeboarding, wakesurfing and snowboarding.

Q: What would you say is the secret to your success?

A: I think it boils down to getting the right people on your team, pointing them in the right direction and getting out of their way! Leadership is not about control; it’s about encouraging others and helping them perform up to their full potential. Everyone wants to feel appreciated and valued.

Copyright 2022 Floor Focus

Related Topics:The Dixie Group, Karastan, RD Weis, Masland Carpets & Rugs, Mohawk Industries