Flooring Forensics - June 2013

By Lew Migliore

When I began my career in the floorcovering industry in 1971, one of the products we sold like hot cakes was residential modular carpet tile. These were boxed shag carpet tiles made with polyester fiber with a cushion back, peel and stick installation and scalloped edges so they’d fit together like a puzzle.

Among the colors were bright yellow, pink, orange, blue and red. In the 1950s, Huega tiles with a hog hair face and bitumen backing were being made and sold in Europe. This product is still being used in CVS stores in the U.S. Milliken and Interface were making fusion-bonded tiles in the late ’70s and early ’80s that were being used in commercial installations. Other manufacturers followed suit. Later, tufted carpet tiles with PVC backings were manufactured when the commercial flooring market started making and selling carpet tiles in earnest. The products back then were bland looking with functionality but little styling. Today, almost everyone making tufted carpet also manufactures carpet tile in a variety of sizes and with extraordinary styling.

Office technology drove the growth of carpet tile, not the marketing hype about how easy it is to change or replace one or several carpet tiles. It was the modular office furniture with open spaces, using more technology—requiring flat cables and the like—that drove the carpet tile market. Replacing one carpet tile when it is damaged or stained was and is rarely done. New replaced tile looks worse and sticks out like a sore thumb for the most part. The ease of installation, transportation and handling further drove the use of carpet tiles. Carpet tiles will easily fit into elevators to be delivered to the floor on which they are to be installed, they can be installed quickly and, with lift systems, new carpet can be installed in a space without breaking down systems furniture and totally disrupting or displacing business operations.

Carpet tiles are the most highly engineered textile floorcovering material in use today. Most carpet tiles consist of layers of material including a stabilizing component. Today, many carpet tile backing components also consist of recycled materials. The backing of the tile that contacts the substrate can be made from a variety of materials including polyurethane cushion and PVC. The use of a cushion backing on carpet tile allows for lower face weights in carpet tile without compromising performance. Over 20 years ago, we tested carpet with cushion backing and face weights as low as eight ounces and compared them to unitary backed carpets with 28 ounce face weights. The eight-ounce product with the cushion backing outperformed the higher face weight product every time. We even drove Hysters (fork lifts) over the carpets for days in carpet warehouses and the products performed magnificently and held together.

Carpet tiles used to come in one size only, but not anymore. There have been tiles as large as 6’x 6’ but today sizes range from just under 20” square to 3’x 3’. That said, rectangular carpet tiles have been introduced to the market and are becoming more popular. In terms of carpet tile design, the patterns themselves are seemingly limitless and the ability to create random patterns on the floor with the use of carpet tiles from mixing patterns and colors to freeform configurations are turning carpet tiles into an art form. Carpet tiles can also be installed in a variety of ways from herringbone to quarter-turned and random. This capability has allowed more flexibility in being able to replace a tile or a section of tile if the space is reconfigured or if an area has been affected by damage such as flooding.

The installation of carpet tiles has also changed. The use of pressure sensitive adhesives is not the only way to install carpet tile anymore. End users, architects and designers are also more reluctant to use adhesives out of a bucket, which have an odor and at the very least the perception that they contain VOCs. As a result, carpet tiles can now be installed using a variety of methods, from Interface’s TacTiles system and Velcro Floor Squares to peel and stick systems (employed by some manufacturers) and EnviroStix, which can be applied to the back of any manufacturer’s carpet tile.

The versatility and variety of carpet tiles make them an ideal textile floorcovering material. Once used only in specific markets and applications, carpet tiles have no bounds anymore. Carpet tiles don’t only occupy corporate open workspace venues or airports but are used in regular office space, hospitality, schools, banks, healthcare and the mainstreet market—or anywhere else you can think of. Carpet tiles are a perfect match for raised access flooring, which are used to run a myriad of electrical, information and technology cables, or climate controlled air, beneath a floor.

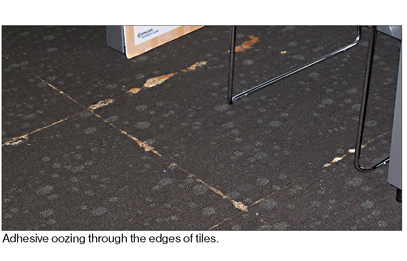

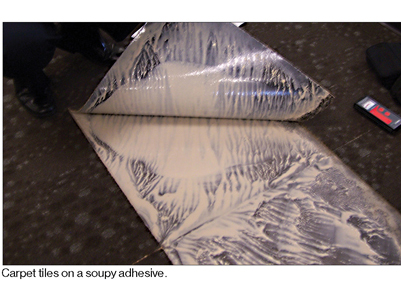

There has also been a proliferation of problems with carpet tiles, both in the past and today. PVC backings do not go well with residual cut-back adhesive. The reaction between the two can cause odors from the PVC backing and oozing of the black cut-back adhesive up through the edges of the carpet tile without any other influences. It is imperative that cut-back adhesive be removed or sealed to prevent these types of problems. It’s a good idea that any black residual material on a substrate be cut back and contained, regardless of the type of flooring being installed over it.

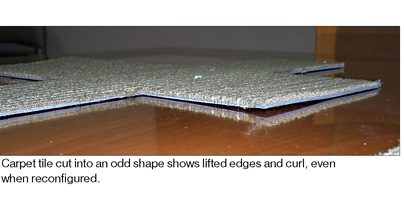

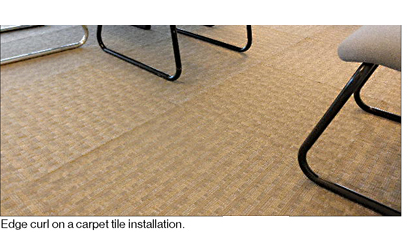

Curling edges on carpet tiles have also been a huge problem in the industry. We saw this condition in the late ’80s as well, so it’s nothing new, it’s just more prolific today and, on any given day, any manufacturer can be faced with the challenge of unstable carpet tiles. This is a highly engineered product with multiple layers. If an imbalance exists in any one of the layered components, it will affect the stability of the product and its ability to lie flat without lifting or curling. Carpet tiles out of the box must be flat, square and stable without exception.

Curling or lifting edges are always the result of an inherent physical characteristic in the carpet tile itself, though the problem is often blamed on moisture in the substrate, poor floor prep, the wrong adhesive or some other outside influence. Carpet tile can sit in moisture unaffected and lie flat over uneven substrates or with swings in heat and humidity. Carpet tiles can be sitting in “soup” with adhesive oozing through the edges and be flat as a pancake. Carpet tile is designed to drape or conform to the floor. To correct lifting or curling in a carpet tile, you shouldn’t have to use an adhesive that is so aggressive it virtually welds the product to the floor. This defeats the whole purpose of the product being modular and removable. It is possible to correct some carpet tile curling using a process that actually bends the carpet tiles in the opposite direction of the curl. This process has been used successfully for decades. Today, there is about a 60% chance of correcting the condition. There are companies that specialize in doing this corrective work. The process involves removing the tile, marking its location, back-bending it and re-installing. When this process works, it can save an entire installation that would otherwise have to be replaced.

Carpet tiles have had an extraordinary influence on the carpet industry. During the latest economic downturn they were a shining star. Manufacturers who thought they had to dial back, anticipating a loss of demand, actually saw just the opposite and had to react quickly as there was no downturn for carpet tile. Now that the market is coming back, we’re regularly seeing projects upwards of 40,000 to 50,000 square yards calling for carpet tile.

Carpet tile growth shows no sign of slowing down. The product has made steady inroads into market segments, such as hospitality, that most people never foresaw. More manufacturers will continue to expand the uses for carpet tile and improve the design. Other manufacturers are entering the market and specialty products are being developed for unique markets. All in all, carpet tile is still the hottest textile floorcovering product available. It has changed the industry and as it continues to evolve, it will continue to improve.

Copyright 2013 Floor Focus

Related Topics:Interface