Jim Neel Discusses Coefficients of Friction

By Jim Neel

Friction is a materials property. Basically, it is the force that resists the sliding motion of one surface against another. Contaminants, such as liquids, can change this value.

The coefficient of friction (COF) is the ratio of the pull force it takes to slide the surfaces divided by the weight pushing down on the surfaces. It may sound a bit complex, but the math is simple. For example, if it takes 30 pounds to push a 60-pound crate across a factory floor, then the COF would be 30/60 or 0.50.

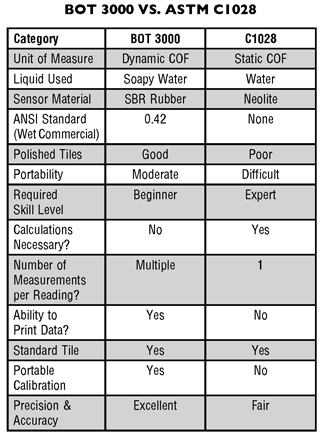

There are two types of friction, static (SCOF) and dynamic (DCOF). SCOF is the ratio of forces necessary to start two surfaces sliding. This is what ASTM C1028 measured. DCOF is the ratio of forces necessary to keep two surfaces sliding. This is what the BOT 3000 is evaluating. There is generally a spike in the force necessary for movement to occur; in other words, you have to push harder to get something moving than you do to keep something moving, so typically SCOF is greater than DCOF.

Slip resistance is the ability of a surface to inhibit the movement of another surface. Although there are many components, the coefficient of friction is thought by many to be an important one. Other factors may include, but are not be limited to, grout joint spacing, tile texture, slope of the floor, and contaminants.

Since the COF can be readily measured, safety professionals often use it to gauge the slip resistance of a floor. A numerical value also makes it a very useful tool for quality assurance at the manufacturing level.

FROM EVOLUTION TO REVOLUTION: HOW DID WE GET HERE?

Historically, tile manufacturers want something relatively simple, statistically repeatable and reproducible, and reliable for processes control. ASTM C1028 filled this role for several decades. During this time, a tremendous amount of historical data was gathered about product performance.

The industry pseudo-standard for SCOF was considered to be 0.60. This value originates from an obsolete ADA bulletin that was published a decade ago (this document was later withdrawn). However, it recommended a minimum SCOF of 0.60 for flat surfaces and a value of 0.80 for ramps. Even though this recommendation was only official for a few years, these values stuck with the tile industry. These numbers were never reflected in ANSI; they were simply what our customers started asking for.

Many consider a COF measurement to be integral to safety, and, therefore, the most important test for floor tile. There is also the potential for increased legal exposure. These factors, coupled with the fact that C1028 has been around for a long time, meant that there were significant political challenges in attempting to improve on the status quo.

In 2001, a device called the Sellmaier FSC 2000 was brought into the main testing lab of Daltile. It seemed to be a promising alternate way of getting SCOF data that correlated quite well with ASTM C1028. The device underwent a series of changes and was later named the Universal Walkway Tester (UWT). At about this time, Daltile took its findings to the Tile Council of North America (TCNA) and the rest of the tile industry. A few years later, the instrument was re-badged as the BOT 3000.

The BOT turned out to be so promising that other (non-tile) groups also started to work with it. On the tile side, the effort took several years. The TCNA Tile Technical Committee further worked on developing a test method around this device.

In slip resistance circles, there is some debate about SCOF versus DCOF techniques and which one best reflects the safety of a floor. While exploring the capabilities of the BOT, the tile industry discovered that there was a very strong correlation between SCOF and DCOF, which essentially made this argument moot.

The BOT 3000 test uses slightly soapy water. This lowers the value from the old 0.60. To assist with educating the marketplace, DCOF was chosen as the technique to use. Basically, we are now measuring something slightly different.

After ten years or so of method development, ANSI A137.1 approved the BOT 3000 as the standard test method for COF. ASTM C1028 was removed as a requirement at the same time. The industry standard is now DCOF as measured per ANSI A137.1-2012 Section 9.6. Also adopted at the same time was a minimum value of 0.42 for areas likely to be walked upon when wet.

The end result is a test method that is not just a modern replacement for C1028; the new method achieves stricter statistical criteria and surpasses alternate methods in just about every category. The ANSI A137.1 test method for DCOF established a new benchmark for COF (and slip resistance) measurement systems.

WHAT IS THE BOT 3000?

The BOT 3000 is a robot that is capable of taking friction measurements of a flooring surface. It is programmable and has the ability to print out and electronically store the data.

This instrument is capable of both laboratory and field measurements. Although the BOT can measure friction in different ways, dynamic COF was chosen as the unit for ceramic tile values. Unlike ASTM C1028, the BOT gives realistic values on high gloss or polished surfaces.

It is important to note that the BOT 3000 instrument is a tool. Tools can be used in different ways. As such, there are other test methods that use this device. Variations in a test method can result in variations of test results. These alternate test methods may yield different results, even if they use the BOT 3000.

A decade of work and research went into the current ceramic tile BOT 3000 (AcuTest) method. There was widespread industry cooperation and participation.

We feel that the method specified in ANSI A137.1-2012 (also called the AcuTest) is the most robust and statistically valid method for COF testing. It should set the benchmark for COF/slip resistance testing in the standards community for years to come.

TRANSLATING THE NUMBERS

Many ceramic tile folks are used to 0.60, so they ask, “What do you mean the number is 0.42? Isn’t that less?” It is important that customers understand that most ceramic tile products (including Daltile’s) have not changed. Most products that met a C1028 value of 0.60 will meet the BOT 3000 AcuTest DCOF value of 0.42.

The BOT is simply measuring something different. ASTM C1028 measures the static coefficient of friction (SCOF). The BOT is measuring the dynamic coefficient of friction (DCOF). And the BOT’s use of slightly soapy water to make the measurement differs from the clean water used in the ASTM test.

Separate research has been done by The University of Wuppertal (Germany), the TCNA, and Daltile over the past ten years. A value of 0.42 DCOF was found to be representative of a slip-resistant surface.

What does the specification of 0.42 DCOF mean? This is the minimum value required by ANSI A137.1-2012 for interior spaces that are expected to be walked on when wet.

Is a product having a DCOF value of 0.42 appropriate for any application? Absolutely not. The specification is intended to be a starting point. DCOF values are only one component of slip resistance. Factors such as, but not limited to, tile texture, number of grout joints, end use conditions, footwear type (or lack thereof), expected maintenance, expected wear, and manufacturers’ guidelines should also be considered.

In general, most tile producers can provide suitable recommendations for using their products in specific usage areas.

Copyright 2013 Floor Focus

Related Topics:Mohawk Industries, Daltile