Light Lab: Mohawk's award-winning design facility is one of a kind - July 2017

By Beth Miller

Last spring, the Mohawk Group opened the doors on one of the more impressive commercial design facilities in the business, called the Light Lab. Designed to host interior designers and end-users, the facility also serves as a workspace for over 100 Mohawk employees focused on product development and design and supporting the firm’s commercial customers. The mid-century modern structure was originally built in the 1960s as the headquarters for World Carpet. After Mohawk acquired World, it served as Mohawk’s residential flooring showroom before Mohawk moved that function to Calhoun. The company gutted the interior of the space and has successfully turned it into an impressive workspace on the top floor with an unequaled single-location pilot lab underneath.

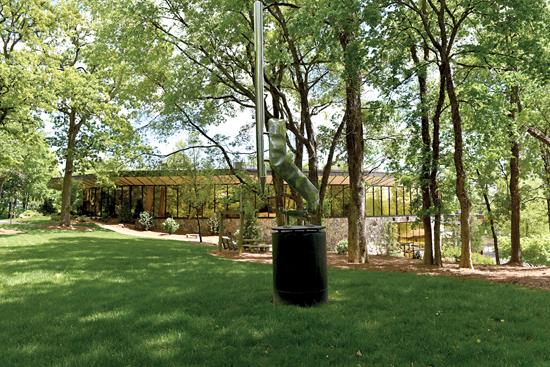

From one of the tallest hills in Dalton, Georgia, the glass walls offer a 360-degree view of the mature trees on the property as well as the mountains in the distance. Artwork, in the form of a large tufting needle, is part of a sculpture garden situated just outside the entrance to the building. As visitors enter, they are greeted by a large red “M” structure that rises up behind the welcome desk, curving over it at the top, accented by lighting. A small detail that might go unnoticed is that the “Light Lab” name displayed on the wall next to the large “M” is made of carpet poms. Blown-up images of various flooring products adorn the opposing wall with actual physical samples resting in a reclaimed wood framework. The facility’s design is progressive in its efforts to provide designers and end-users with an open-office environment for collaboration on projects.

The 33,000-square-foot facility was completely gutted to accommodate the new interior space design. The materials were repurposed from within the building as well as from other Mohawk facilities. The interior space redesign was a collaborative effort with Savannah School of Art and Design students, who also supplied the “Light Lab” moniker. Mohawk pulled pilot machinery from weaving pilot plants-in Eden, North Carolina; Landrum, South Carolina; and Glasgow, Virginia-as well as equipment from its Virgil Drive facility in Dalton to build its 40,000 square-foot pilot plant, just an elevator ride from the Light Lab.

The pilot plant has the ability to produce miniature tufted and woven versions of full-size carpet. Starting in the Light Lab, designers and end-users now have the opportunity to lay out the project concept in the morning and go view the newly made samples in the pilot plant after lunch. The pilot equipment has the same capabilities as Mohawk’s full-scale carpet manufacturing plant, providing designers with a spectrum of carpet design options in a miniature product.

In May 2016, Mohawk became the first building in Georgia to receive the Living Building Challenge (LBC) Petal Certification from the International Living Future Institute (ILFI). According to ILFI’s website, “The Living Building Challenge is a green building certification program and sustainable design framework that visualizes the ideal for the built environment. It uses the metaphor of a flower because the ideal built environment should function as cleanly and efficiently as a flower.” There are seven performance categories, called Petals: place, water, energy, health and happiness, materials, equity, and beauty. In order to receive Petal recognition, a building project must satisfy the requirements in at least three categories with at least one being water, energy or materials. Mohawk Group’s Light Lab satisfied the requirements for place, health and happiness, materials, equity, and beauty. Currently, the LBC is the most rigorous measure of sustainability in the built environment in the world, according to ILFI.

Copyright 2017 Floor Focus

Related Topics:Mohawk Industries