Design Trends in Education - May 2016

By Calista Sprague

Flush with money from endowments, college campuses across the U.S. are abuzz with construction projects, and many are incorporating new learning environments designed to promote innovation and entrepreneurial pursuits. The new workplace penchant for collaboration and engagement has even trickled down to K-12 education, causing shifts in flooring specification for the entire education sector. Now, in addition to durability, flooring products also tout flexibility to be considered for today’s schools.

FLOORING CATEGORIES VIE FOR MARKETSHARE

In the education market, resilient flooring makes up around half of the marketshare, soft surface accounts for about a third, and the remaining 10% to 15% comes from ceramic tile, a breakdown that has held fairly steady in recent years. The biggest shifts are currently happening within soft surface and within resilient, and less so between the categories.

Carpet tile has been steadily taking share from broadloom in the education sector, preferred for its ease of installation, increased design options and flexibility for moving and replacing tiles once installed. In addition, although at first blush carpet tile may be more expensive per square foot than broadloom, once installed they may be nearly identical in price. Carpet tile’s modularity allows for very little waste compared to large rolls of broadloom. Also, carpet tile is faster to install, helping schools save on labor costs. In fact, designers say that some facilities departments may be able to do carpet tile installations themselves, eliminating labor costs altogether.

In the resilient category, LVT is taking share mainly from VCT. Like carpet tile, LVT is modular, making it a more flexible product when it comes to design options. In addition, school systems and, more specifically, facility managers have become more aware of the importance of lifecycle costs for flooring compared to initial costs. Although LVT carries a higher purchase price, it can be quickly and easily cleaned with a damp mop, whereas VCT requires periodic stripping and waxing, ultimately costing schools more over its lifespan.

Despite its higher maintenance costs in stripping and polishing machinery, chemicals and labor, VCT still occupies a significant percentage of the education market. Especially in K-12 schools, where construction budgets remain tighter, the bottom line at the time of installation may win out over long-term maintenance costs.

Designers say that sometimes a school system may prefer to install LVT or another resilient product, knowing it would be financially advantageous in the long run, but find themselves limited because funds have already been allocated for the renovation. Many times schools have no way to apply future maintenance savings to cover the higher purchase price of LVT.

LVT is also taking a bit of share from soft surface in small areas within K-12 classrooms. Rooms that were once carpeted wall to wall now often have small sections of LVT for ease of cleaning near sinks or in areas where hands-on projects might get messy. The modularity of both carpet tile and LVT make these combined installations more straightforward and easy to alter, should a teacher want to reconfigure the classroom.

In higher education, LVT is taking share from both VCT and soft surface mainly in residence halls, where wood looks are installed for a higher end residential design meant to attract and retain students. Although LVT is specified for other areas of college campuses, its increased use in residence halls during the past couple of years represents a significant design trend and category shift toward hard surfaces in dorm rooms that continues to grow.

INNOVATIVE HIGHER EDUCATION DESIGN

Whereas residence hall design mimics residential trends, other areas of the campus are borrowing from the corporate sector. Inspired by tech startups, new so-called incubation labs and maker spaces are cropping up at universities on both coasts and points in between. Swirling amongst the construction dust are new classroom buzzwords like multimodal, entrepreneurial, interactive, flexible and engaging.

Universities and other higher education institutions are developing large open spaces for students to brainstorm, collaborate, experiment and create with peers, faculty members and industry partners. Rooted in the success of companies like Google and Facebook, both started by college students, and Apple, which like so many other start-ups was launched in a garage, the spaces seek to acknowledge and encourage the potential innovations that bright students may bring to the fore when given the freedom to explore possibilities beyond the restrictions of a traditional classroom or computer lab.

Some universities use the incubators to partner with local companies, giving students opportunities to interact with professionals from their chosen field of study. The students gain access to real world information and issues while making personal connections that could lead to future employment. In turn, the companies draw on fresh ideas and input from students, also taking advantage of the networking possibilities to recruit young talent.

Top global design firm Gensler has created academic incubator designs for several institutions in recent months. “Whether it’s business schools or libraries, they are creating a more raw, flexible space to allow students more creative collaboration,” says Allie Trachsel, interior designer in the education practice area at Gensler’s San Francisco office. “It’s garage innovation meets higher education.”

Northwestern University, just north of Chicago, took the garage theme fairly literally, hiring Gensler to create an incubation space on the second floor of a new parking garage. Aptly named The Garage, the space plays up the theme with garage doors and parking space markings on the floor. Despite its tongue-in-cheek design approach, The Garage, which opened last June, hosts serious classes and workshops along with informal meetings, mentoring sessions and opportunities for students just to tinker.

Gensler also designed the International Design Centre for MIT at its Cambridge, Massachusetts campus, where students can collaborate with peers from the Singapore University of Technology and Design to work on global issues in engineering and architectural design. The space has an industrial feel, with large workbenches on casters, shop stools, rolling utility carts and massive whiteboards. Students not only benefit from working with their international cohorts, but they also have the opportunity to brainstorm and problem solve across curriculum lines, allowing for interdisciplinary solutions.

FLOORING FOR INNOVATION SPACES

Academic incubators offer students a link between the classroom and the workplace, and the designs appropriately borrow more from workplace design than do typical education environments, often reflecting the interiors of trendy entrepreneurial start-ups and tech companies.

Trachsel says that although the popularity of the industrial look has led to increased use of concrete floors, acoustical issues often lead to alternative specifications. She points out that if concrete is chosen for the flooring, then acoustic solutions must be incorporated elsewhere, such as the ceiling or walls. Often clients desire an open ceiling with exposed pipes and ducts along with whiteboards on the walls, so they opt for a more acoustical choice for the floor. Rubber or some other resilient is a common choice and sometimes carpet tile or a combination is specified to improve acoustics in the wide open spaces.

Among resilient options, Trachsel prefers rubber when the budget allows. She also says that the dramatically improved visuals in LVT make it a viable choice when rubber is not an option. She specifies sheet goods, including linoleum and vinyl, especially for spaces like laboratories.

COLUMBIA COLLEGE DESIGN LAB

Many incubation spaces center on science and technology, but Trachsel recently worked with a team from Gensler to renovate two floors of a building that houses the Art & Design School on Columbia College’s campus in Chicago. The renovation coincided with a shift in curriculum toward a more hands-on, laboratory learning environment for the multidisciplinary design school, which led to a different approach to flooring.

One level of the building was dedicated mainly to classroom and studio space. Traditionally, the school has utilized separate lecture, studio and computer lab rooms, but the new design incorporated all three functions into larger open areas referred to as integrated design studios.

For the elevator lobby, Gensler specified an Interface carpet tile, part of a previously developed building standard, in a vibrant orange, and the intense color continues up the walls, lending its energy to the lobby. Two tones of grey carpet tiles line the corridors, laid in alternating color blocks.

The design school uses the walls in the corridors to display student work, so the grey carpet provides a neutral backdrop that won’t compete visually with the art and also provides acoustic benefits.

Traditionally the university has relied on VCT for its classrooms, and concrete was also considered for this project to contribute to the desired industrial feel. But the integrated studios are larger than conventional classrooms and feature open ceilings, so the flooring needed to assist with sound absorption. The school opted to invest in sheet rubber, which bears a higher initial cost but offers durability, low maintenance and greater acoustical benefits, and also feels softer underfoot for students and faculty working in the space. Once again, a neutral grey was chosen to keep the spotlight on student art.

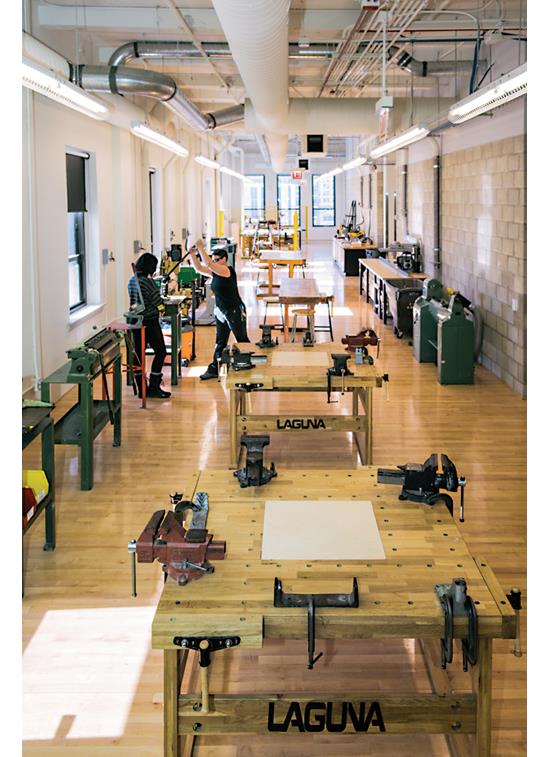

The second floor houses the design school’s wood shop. A hard surface was a requirement for the floor of the shop, which is filled with large woodworking equipment. Again, concrete was considered, but was passed over in favor of a maple hardwood. “It brings a hint of warmth to a space that, with all the industrial equipment, could feel sterile and cold,” explains Traschel. The hardwood will stand up to abuse and can be sanded down occasionally to buff out blemishes or can be left to develop character over time for an authentic distressed look.

K-12 DESIGN TRENDS

While industrial looks generally do not translate to K-12 schools, many of the higher education buzzwords do. Multimodal, interdisciplinary, innovative, interactive, collaborative, experiential and flexible are all terms commonly used to describe contemporary classrooms for both K-12 and higher ed.

Of all the classroom descriptors, flexible is perhaps the most influential in current K-12 design. Teachers once stood in front of the classroom and relayed information to students sitting in neat rows of desks or tables, and the furniture rarely moved. Today’s teachers, however, are more likely to set classrooms up in zones with students doing hands-on or collaborative work in small groups that might be sitting on the floor, at a table or gathered around a whiteboard. Furniture configurations may change weekly or even daily to accommodate project-based rather than lecture-based lesson plans.

Classrooms also need to be flexible in response to fluctuating student populations and student to teacher ratios. Varying numbers of students enter kindergarten each fall, and neighborhoods expand and contract, causing each grade’s numbers to vary from one year to the next. Alterations in state and local policies with regard to student to teacher ratios also affect annual classroom numbers.

Schools with older facilities find it difficult to adapt to these continual shifts in student population sizes, so many newer schools are being designed with movable walls to accommodate expanding or shrinking class sizes year to year.

FLOORING FOR MODERN CLASSROOMS

Modular flooring has become the preferred choice for K-12 schools that are incorporating contemporary flexible spaces. Carpet tile, LVT and rubber tiles can all be easily installed and reconfigured to suit the evolving needs of a school or of an individual classroom.

Christopher Novack, interior designer at Southern A & E in Atlanta, specializes in K-12 education projects. He says that schools are shifting away from both the rigidity and costly maintenance of VCT in favor of low maintenance modular options. LVT is one of the fastest growing categories in K-12, taking share mainly from VCT. Manufacturers say that LVT’s higher initial cost can be recouped in just two to three years due to its low maintenance costs, and its superior visuals help make it a popular choice as well. Rubber is also growing in specification, both in sheet and tiles, prized for its softness underfoot, acoustic properties, durability and cleanability.

Rubber is routinely installed on concrete slabs in schools, and even performs well in damp areas like locker rooms, where the product may get wet on the surface. However, Novack warns that rubber is not suitable for areas with excess subfloor moisture. “We’ve had issues in a couple of schools where the clients wanted to put rubber down,” says Novack. “But the concrete was just so old, it was too difficult to remediate moisture issues.” Water seeping up through a concrete slab can cause installation failures, breaking down adhesives and adversely affecting even the rubber itself. In these cases, ceramic tile is usually recommended.

Novack reports that porcelain tile is also showing some growth in education specification, especially for high visibility and high traffic areas, like main entryways, or for high abuse areas like cafeterias. “The cafeteria floor is the most abused surface, dragging tables back and forth across it. Schools want something that’s not going to scratch, so we’ve seen a push for porcelain—unglazed through-body tile—for cafeterias, installed with epoxy grout, which is significantly more durable than a standard latex sanded grout.”

Designers are specifying porcelain more frequently for restrooms, which along with kitchens traditionally have been covered in commodity quarry tile. Novack echoed the need expressed by designers from other commercial sectors for smaller coordinating porcelain tiles to accommodate drains in restroom floors. “For many years we used smaller 2”x2” mosaic tiles, but we have seen a rise in requests for larger format tiles,” he explains. “We run into a problem with sloping to the drain, though. Manufacturers for years were selling an 8”x8” or 6”x6” through-body porcelain for us, but they started to eliminate those, so sometimes we have to use 12”x12” tiles and cut them down.”

Novack has noted a recent rise in the use of resin floors with vinyl flake inclusions for K-12 restrooms as well. The result is a durable monolithic floor that cleans easily and looks similar to terrazzo.

In classrooms, carpet tile is a common choice, especially for primary schools where students often sit on the floor for reading and other activities. Most school systems request glueless installation with adhesive tabs for ease of replacement, and designers look for tiles with mergeable dye lots to make replacement tiles less noticeable. In addition to flexibility and comfort underfoot, modular carpet offers improved acoustics. Sound control has always been an issue in education, but it has become even more important in contemporary schools, where several activities may be happening simultaneously within a single classroom.

In recent months, schools have been requesting concrete floors more often, in the hopes of saving money. But the designers point out that stained and polished concrete does not necessarily offer cost savings, and in many situations is simply not a viable option.

Schools are generally built on concrete slabs, so it stands to reason that it must be cheaper to stain and polish a surface that is already there than to purchase and install another floorcovering. However, the majority of school projects involve renovations rather than new builds, and the existing concrete is often in rough shape, with cracks from settling, uneven patches from repairs, residual glue from previous flooring installations and other blemishes.

Even in new installations, polished concrete must be specified before construction begins in order to ensure that the concrete surface gets a fine finish. Concrete subfloors are meant to be covered and therefore tend to have a rough and unattractive surface that cannot be hidden with stain and polish. Skim coating the floor is an option in some cases, but not for a slab with recent movement or extensive cracks. And labor for the skim coating, staining and polishing adds up, often dissolving any overall cost savings.

COOSA HIGH SCHOOL IN GEORGIA

The Floyd County School District recently hired a design team from Southern A & E for an ongoing two-phase project for Coosa High School outside Rome, Georgia. More than 111,000 square feet of flooring choices carry a great deal of the design interest in the main academic building.

Overall plans included new construction for the three-story academic building and demolition of the original building. In phase two, a new gymnasium will be built, and a fine arts center will be created through the renovation of the existing band and choral spaces and the addition of a new theater.

Christopher Novack worked on the team during phase one, designing the new academic building that was completed in November 2015. He says the clients desired a more modern school with upgraded finishes and school colors throughout.

The use of school colors actually posed a major challenge for the design team. The strict palette of black, white and grey was limiting and cold. “Typically in a high school they want a little flash of color, but we could not incorporate any other color because the rest of the system’s high schools used the majority of the accent colors,” Novack explains.

The designers cleverly turned to wood and wood-look surfaces as an accent to avoid other teams’ colors while warming up an otherwise stark palette.

In the new lobby, visitors are greeted by a large school crest made of LVT from Tandus Centiva’s Coral Reef Collection and surrounded by a field of wood-look LVT from Armstrong’s Natural Creations Mystix line. A strong black border helps set off the crest from the wood visual.

Mohawk’s Rediscovered modular carpet from the New Vintage collection in Top Notch was specified for the adjoining administrative areas. The tiles feature a mixture of deconstructed textile patterns in charcoal that fade in and out of a lighter grey background. The patterns are interrupted by narrow white and grey ticking, which also fades in and out for an upscale vintage feel. The plank format carpet tiles were laid in a herringbone pattern for additional interest, mirroring a similar pattern in the corridor flooring throughout the school.

The same Mohawk carpet tiles appear in the media center, except around the circulation desk, where cork from Capri Cork was specified. The cork brought in a hard surface without sacrificing acoustics, and the natural color coordinates with the wood-look LVT.

For the main corridors, the budget did not allow for LVT, so once beyond the lobby’s double doors, the flooring transitions to VCT. Armstrong’s Striations polyester composition tiles, PVC free with 3% bio-based content, were selected for the first floor corridors and cafeteria, which are frequented by visitors, while traditional VCT was used on the less public upper floors.

Rather than traditional block or checkerboard patterns, VCT planks and squares in black, white and grey were laid out in a large herringbone pattern, bringing energy and modern interest to what otherwise might have looked like institutional flooring.

VCT was also specified for the classrooms, per the school system’s request, but porcelain tile was installed in science classrooms where chemicals might be spilled. Quarry tile lines the kitchen floors, and vinyl flake resin was poured in the restrooms.

Phase two of the Coosa High project is now underway and will include 66,000 more square feet of flooring. LVT has been chosen for the gym lobby, and the basketball court will sport a traditional raised hardwood floor. In the arts center, rubber will be installed in the band and choral spaces with LVT for the theater.

The K-12 market is growing as well, although not as rapidly, since its projects depend so heavily on government funding, which has not yet returned to pre-recession levels. Still, flooring manufacturers report a steady increase in K-12 renovation projects and note that new builds are finally beginning to break ground with more frequency after all but disappearing during the Great Recession.

The K-12 market holds plenty of pent up demand. According to the NEA (National Education Association) school systems would need to spend $197 billion just to bring all U.S. schools up to “good overall condition,” to say nothing of modernization. As long as the economy continues to strengthen and state and local budgets rebound, an increasing number of school projects will enter the pipeline.

Copyright 2016 Floor Focus

Related Topics:Interface, Armstrong Flooring, Mohawk Industries