Pharr Yarns: On the Move - Feb 2015

By Kemp Harr

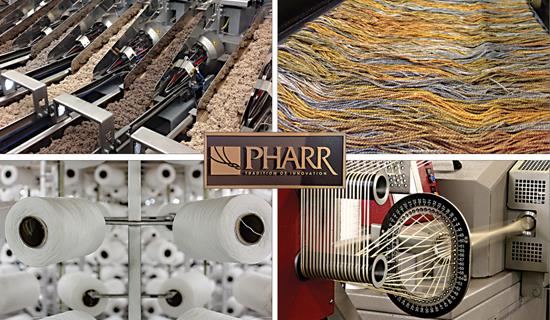

For many years, Pharr Yarns has lived under the radar, quietly retooling and growing to become an integral supplier to the carpet industry. With the recent news that Pharr has taken full ownership of Phenix Flooring and with the company’s recent celebration of its 75th anniversary, Pharr is a company on the move with an interesting story to tell.

Not only does the company operate one of the largest sales yarn companies but it now owns one of the top ten carpet mills in the U.S., along with three other successful businesses. Pharr’s sales yarn business services carpet mills around the world with a distinctive mix of face yarns. As you’ll learn from reading this article, Pharr’s success story is one of a family-run company that understands the value of diversity and continued investment in strategic areas.

The birth of Pharr Yarns began in 1939 when three family members decided to reopen the McAden textile mill in McAdenville, North Carolina, which had been shuttered for four years due to loss of business and labor issues brought about by the Great Depression. The three family members—Robert Stowe, Daniel Stowe and William Pharr—reopened the mill and called it Stowe Pharr Mills. Their goal at the time was to pump new life into a factory that for many years served as the lifeblood of the small town of McAdenville, which sits just west of Charlotte. In fact, as the name of the town implies, McAdenville was established around the McAden mill, which in 1881 had been built on the shore of the Catawba River, so the river’s current could power its equipment. A portion of the original mill is still standing today as part of Pharr’s headquarters.

|

BROAD EXPERTIESE |

|

Pharr’s diversity extends deep within the yarn business itself. It has expertise in handling both types of nylon (6 and 6,6) as well as polyester and triexta. Its denier range goes from 960 to 2600 and from three to 25 denier per filament. From a processing perspective, Pharr offers extrusion, crimping, spinning, twisting, two types of heat setting (Superba and Suessen), space dyeing, and remelt. Today, the end products for Pharr’s carpet yarns include everything from high-end carpet tiles to living room broadloom, area rugs, automotive floorcovering and even industrial mats. The company employs 1,500 people in operations in North Carolina, South Carolina and Georgia. |

Pharr’s business is thriving today, due in part to the diversity of its five businesses. Back in 1939, its focus was split between a sales yarn company and a real estate holding/investment company. The yarn business grew quickly as the depression ended and demand for fiber picked up as a result of World War II. Little by little, one division helped fund the growth of the other, and now the company operates five businesses: carpet yarn, high performance specialty (heat and cut resistant) apparel yarn, real estate development, hotel property management and now residential carpet.

From its start in the late ’30s until the early ’50s, Pharr’s yarn business was focused on spinning natural fibers for the apparel business. In 1950, it started working closely with DuPont and eventually with Monsanto on spinning synthetic fibers for the carpet industry. Throughout the years, Pharr has maintained its edge in the fiber business by reinvesting in the latest processing equipment and nurturing its relationships with key equipment manufacturers, who, in turn, provide insight into where technology might lead the business. In 2006, for example, Pharr was one of the first companies to purchase an Oerlikon S5 extruder, which has revolutionized the carpet yarn business as it has rapidly shifted from spun yarn to bulked continuous filament (BCF).

In the last ten years, Pharr has invested $70 million in new equipment. This level of investment, under any circumstance, shows the intestinal fortitude of the company’s leadership, but when you factor in that this was during the same recessionary period when the carpet industry’s demand for fiber dropped from three billion pounds to 1.8 billion pounds, it’s nothing short of bold. Fortunately, while the carpet yarn business was shrinking and retooling, the company’s high performance specialty yarn business was servicing the U.S. military with Kevlar and other high strength, heat resistant products that were in high demand due to the Iraq and Afghanistan wars.

Today, the 76 year old business is led by Bill Carstarphen, president and CEO and third generation of the family. Bill’s mother, Catherine Anne, was the daughter of William Pharr, and Bill’s father, Bip, ran the business for more than 50 years. Bill—who’s been active in the business for many years—took the reigns as the leader when his father passed away last year.

There is also a leadership transition occurring in Pharr Yarn’s business: Woody Gosney will retire as president in March after almost 43 years with the company, and Rich Pattinson will step into the position.

The story on Pharr must include more details on Phenix Flooring, which has grown to become one of the top ten carpet mills in the U.S. Back in 2003, when Phenix first got started, it focused on producing solution-dyed PET carpet to a short list of high volume retail chains. But today, under the leadership of Mark Clayton, the business has branched out into a broader range of styling and has added solution-dyed nylon 6,6 to its already broad product line. It has also expanded its reach toward consumers by servicing a broad range of retailers, both small and large. And now that Phenix is part of the Pharr family, it is vertically integrated from chip to customer.

Pharr Yarns has been a player in the carpet business for 65 years. The company has seen its customer base grow up to 300 mills, then dwindle down to a couple of dozen. We’ve watched as the big mills in this business have backward integrated and brought most of the ingredients they need to produce carpet in-house. It’s refreshing to see a company like Pharr, which has adapted to be a core supplier to all the mills for specialty yarns and has also found its niche in the carpet business. Pharr has found success by servicing its customers and continuously reinvesting in its business. The business may have gotten its start by firing up an old mill and restoring life to McAdenville, but it has stayed alive by being strategic about its investments, hiring great talent and focusing on its customers.

|

CHRISTMAS TOWN USA |

|

Back in 1956, Pharr Yarns started decorating McAdenville with strings of colored lights. This event has grown to become known throughout the region as Christmas Town USA. Pharr’s tree lighting team works seven months a year in preparation for this elaborate 26-day celebration of the birth of Christ. Each year, over 600,000 visitors are drawn to this attraction. |

Copyright 2015 Floor Focus

Related Topics:Phenix Flooring, The International Surface Event (TISE)